Hence, today’s manufacturing companies aim to ensure minimal system downtime. To address this problem, the best-proven solution is Predictive Maintenance (PdM), which foresees the application of IoT sensors, Machine Learning, Artificial Intelligence, and everything related to smart technologies to identify and prevent equipment failure before it occurs.

This blog will discuss how predictive maintenance works, its application in avoiding downtime, the advantages of this procedure, and its application to the production floor of a factory to increase the lifespan of the equipment.

What is Predictive Maintenance?

Predictive maintenance identifies that equipment will eventually fail and can be scheduled to be maintained as soon as possible to rectify the problem. While the first type merely repairs machines after they have failed, the second type is regular maintenance. Even if the machine does not show signs of failure, predictive analytics in big data Uses real-time data from the sensors to determine when the machine will likely fail.

Using technologies like IoT, AI, and machine learning algorithms, predictive maintenance helps always assess the health of the machines and proactively tell when a machine needs repairs or changes. This approach allows manufacturing companies to lower downtime, increase resource efficiency, and prolong the working life of their equipment.

The Role of Predictive Maintenance in Preventing Downtime

Lack of schedule is one of the biggest problems that manufacturing plants face, especially today. It hampers production, delays orders, raises repair costs, and kills the reputation of a business. Predictive maintenance addresses this issue by offering several key advantages:

- Proactive Problem Solving: On the other hand, predictive maintenance helps manufacturers predict when equipment components will likely go wrong. It enables us to detect growing machine conditions, such as machinery vibrations, operating temperature, or wear and tear, at an early stage. Once these have been established, maintenance can be planned to avoid a complete equipment breakdown.

- Reduced Unplanned Downtime: The PdM enables a manufacturer to anticipate when a failure is likely to occur and schedule the repair time when production will not be affected, hence saving costs. This has made it possible to minimize the cases of unanticipated interruptions in operations and execute production schedules as planned without Interruptions.

- Improved Resource Allocation: Predictive maintenance also assists management in determining when resources need to be used by reducing the number of unnecessary precautionary maintenance operations and, in turn, the consumption of spare parts. When information is used optimally, maintenance teams can focus on the most important tasks, requiring only those parts and tools to cut costs while enhancing efficiency.

- Extended Equipment Lifespan: Regular supervision helps us identify problems in their early stages so that small problems cannot culminate in large failures. This saves much money on expensive repair and replacement, prolonging the service life of very costly industrial equipment.

How Predictive Maintenance Works

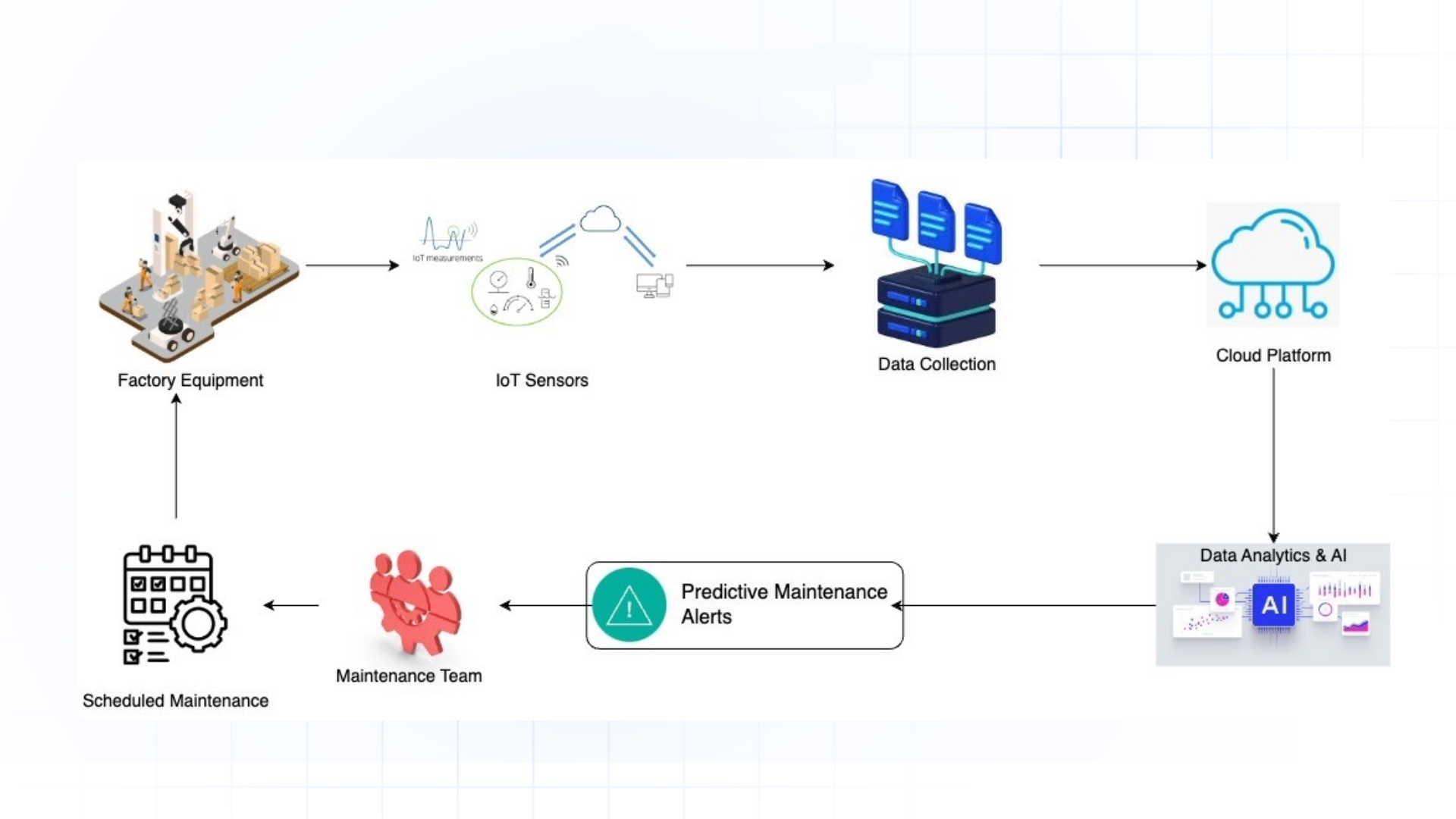

In the context of factories, predictive maintenance comprises some components, technologies, and processes. Next is the general description of how PdM is done in an ordinary manufacturing environment.

- Sensors and IoT Devices: The first step is to place sensors and IoT devices on equipment to gather data about their condition. These include temperature, vibration, pressure, and noise sensors, which reflect the health of the monitored equipment. The collected data flows to a central system for analysis in real-time.

- Data Analytics and Machine Learning: The data thus collected feeds data analytics and applied informatics involving machine learning to determine the equipment’s performance over time. Performance patterns are analyzed to compare current data to prior performances to note problems that may result in failures.

- Failure Prediction: Other advanced AI and machine learning methods, such as predictive models, are then applied to estimate the time a failure occurs. These models incorporate aspects of age, speed, conditions under which the machine is used, and general degradation of the individual parts to try to find the remaining useful life (RUL) of the equipment.

- Maintenance Alerts and Scheduling: The system uses predictions to notify the maintenance teams to attend to issues before a failure is recorded. Maintenance work can be carried out during times of low production to reduce the interruption of manufacturing.

- Feedback Loop: Once maintenance is carried out on the equipment, the system will continue to monitor it, providing feedback that will enhance further modelling for better predictions in the future.

Benefits of Predictive Maintenance

Predictive maintenance has numerous advantages that can enhance the system’s efficiency in the factory environment.

| Benefit | Description |

| Reduced Downtime | Since this approach maintains the product line in advance if it is likely to fail, it avoids unnecessary time off or production downtime. |

| Increased Productivity | As such, machines spend minimal time on breakdowns, increasing production rates. |

| Lower Maintenance Costs | Low maintenance levels allow manufacturers to avoid regular part replacement, reducing repair costs and the costs of the relevant materials. |

| Extended Equipment Life | The best thing about it is that it can determine the equipment lifecycle and ensure it does not break down. |

| Improved Safety | Maintenance prediction not only reduces the chances of equipment breakdowns, which may lead to the development of hazards or accidents on the production floor, but it does so in time, which helps avoid inconveniences. |

| Better Resource Management | It also dramatically reduces the number of issues that deserve attention but are not significant enough to warrant maintenance resources or time, thereby increasing workforce productivity. |

Use Case of Predictive Maintenance in a Factory Setting

| Use Case | Equipment | Benefits |

| Predictive Motor Failure Detection | Electric Motors | It reduces the chances of unanticipated equipment failure and increases the motor’s lifetime. |

| Vibration Monitoring for Pumps | Pumps and Compressors | It aims to predict failure and reduce repair costs. |

| Temperature Monitoring of Bearings | Bearings | It reduces the chances of overheating and increases the service time of bearings. |

| Predictive Maintenance for CNC Machines | CNC Machines | Reduces downtime for product creation and improves schedule planning. |

| Monitoring Hydraulic Systems | Hydraulic Machines | This prevents water leaks, hence saving maintenance costs. |

So, let’s consider an actual example of the application of predictive maintenance we talked about earlier – a factory producing spare parts for heavy machines and equipment. This factory uses several CNC (Computer Numerical Control) machines that are widely used in production.

Scenario: Currently, the factory records high levels of time wastage resulting from breakdowns of its CNC machines. These discrepancies negatively impact production, raising repair costs and decreasing factory productivity.

Solution: The factory selects a field to employ a predictive maintenance system. The CNC machines’ parameters, such as vibration temperature and spindle speed, are all fitted with sensors. Information gathered from these sensors is processed by machine learning techniques to capture beyond-gaussian patterns associated with failures.

For example, the predictive maintenance system may discover a rise in vibration intensity from one of the CNC machines to indicate the wearing of the bearings. It then triggers an alarm for the maintenance department to affect a repair during off-peak production time. But if the factory addresses the issue before bearing failures fully, it would serve the interest of the factory in the sense that it will prevent a total breakdown that would disrupt production, causing the factory to incur huge losses. Predictive analytics models.

Outcome: By employing predictive maintenance, the factory realizes a 40% decrease in the number of times a machine experiences an unexpected breakdown, thus enhancing the amount of time that specific machinery or equipment spends operational. The alleviation of frequent breakdowns and improved repairs also constitute an added saving on the expenses of maintained parts.

Challenges of Implementing Predictive Maintenance

While predictive maintenance offers numerous advantages, its implementation does come with certain challenges:

- Initial Setup Costs: Implementing sensors, adopting data analytics platforms, and educating employees is not cheap. Due to the costs involved, it may be particularly challenging for small manufacturers to make the necessary investments.

- Data Management: Processing a large volume of real-time data can be challenging mainly because a significant amount of data needs to be engaged, and the accuracy of the predictions depends on the capability of the data infrastructure and data analytics.

- Team Member Training: Operators require training to understand the alert generated due to predictive maintenance and how to incorporate it into their working environment.

- System Integration: The latest ways to bring predictive maintenance into maintenance management and manufacturing schemes can redesign the processes and procedures.

Conclusion

Overall, predictive maintenance is a strong tool to address manufacturers’ concerns about minimizing downtime, maximizing productivity, and containing operational maintenance costs. By using IoT, AI and machine learning techniques, factories can have preventive planning of equipment failures without having to occur. Considering the facts regarding the industry’s future, predictive maintenance is set to become more significant in decentralising factories’ key processes and become a key approach vital for long-term factory operations.